While this resin has been manufactured to resist scratching and resistance to marking from heat sources we must stress this resin will still mark if sharp items are moved across the surface or hot items are placed on the surface.

As with all casting products, we stress that customers should purchase a small amount to perform initial tests to ensure suitability for their project and requirements.

| Product Data | Units | Mix |

| Mix Ratio | Weight | 100 : 50 |

| Hardness | ShoreD | 80 – 85 |

| Viscosity (25°C) | mPa.s | 600 – 900 |

| Density (25°C) | g/cm3 | 1.09 – 1.13 |

| Pot life (200g, 25°C) | Mins | 25 – 30 |

| Cure Time (200g, 25°C) | Hours | 24 |

| Full Cure (25°C) | Days | 7 |

| Recommended Casting Thickness | mm | 1 – 5 |

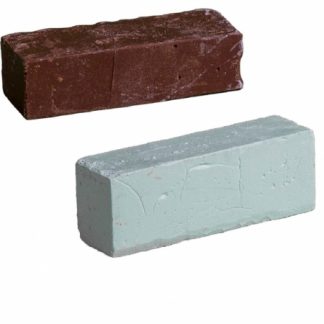

Pigmentation

Epoxy pigments are the recommended system to colour this resin however the polyester range of pigments will also work.

Please read the Technical and Safety Data sheets prior to use.

We recommend small scale testing to ensure compatibility before using at full scale.

Cold Weather Notice

Cooler temperatures in the UK and Ireland around mid-autumn to mid spring are not ideal conditions for water clear epoxy systems, this can increase the chances of crystallisation in the resin (this can occur at room temperature depending on circumstances, it is however much less common). Appearance can differ depending on the degree of crystallisation, from small lumps sitting on the surface to a hazy/milky white appearance, extreme cases the contents may completely solidify. Crystallisation occurs due to a phase change from liquid or solid similar to that of water turning to ice, fortunately it is easily reversed by warming the epoxy component to 60°c. Ensure any crystals are completely removed as remaining crystals can act as a seed causing the crystals to form again quite quickly. Lab results show the heating cycle to remove crystals can be repeated on multiple occasions before beginning to suffer from any losses in resin properties. We recommend keeping the resin system at a good room temperature at all times where possible, ensure to clean the lids and bottle necks of containers with isopropyl alcohol / acetone allowing the solvent to evaporate before replacing the lid.