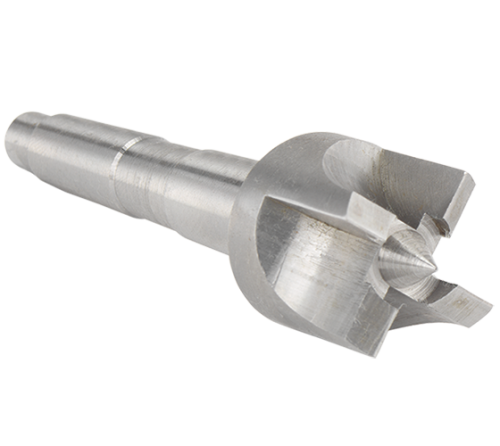

The central locating pin of the drive centre retracts into its body when pressure is applied from the lathe tailstock, leaving the ring of teeth around the circumference to hold the workpiece extremely securely, with clamping pressure spread evenly across the teeth. The retraction of the locating pin means it cannot split the timber, making it ideal for use with smaller and more delicate work.

The locating pin tension is adjustable, allowing for lower tension to be set for small, delicate workpieces and higher tension for use with hard woods and large timbers.

Another key benefit of this design is that the workpiece can be removed from the lathe if required and easily repositioned, using the indentations created by the locating pin and ring of teeth as an accurate guide.