-

Out of stock

Aids in removing cured superglues from skin and work surfaces. Debonding agent for all super glues. Always test first. 1-oz bottle.

Aids in removing cured superglues from skin and work surfaces. Debonding agent for all super glues. Always test first. 1-oz bottle. -

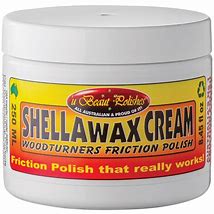

A one-application woodturners friction polish that really does work and is ideal for use on smaller spindle work such as pens and similar objects up to around 10 cm (4") diameter. This exceptional polish is made using a specially formulated hard shellac as a base to give a harder, more durable finish, giving greater resistance to marks and blemishes from water, alcohol and heat. Normally applied directly onto bare timber (though it can be used over most oils too – but test on scrap first) this polish dries almost instantly yet goes on hardening for up to three weeks resulting in a truly durable finish which far exceeds others on the market today. Once fully cured the finish is food-safe and non-toxic.

A one-application woodturners friction polish that really does work and is ideal for use on smaller spindle work such as pens and similar objects up to around 10 cm (4") diameter. This exceptional polish is made using a specially formulated hard shellac as a base to give a harder, more durable finish, giving greater resistance to marks and blemishes from water, alcohol and heat. Normally applied directly onto bare timber (though it can be used over most oils too – but test on scrap first) this polish dries almost instantly yet goes on hardening for up to three weeks resulting in a truly durable finish which far exceeds others on the market today. Once fully cured the finish is food-safe and non-toxic.

-

Out of stock

Shellawax Glow is darker than regular Shellawax (a deep honey to tan colour). It is made from a special blend of shellacs and is designed to give more depth and richness to highly figured timbers like fiddleback, birdseye, flame and quilted woods. It will also give more richness and a sense of depth to many other timbers.

Shellawax Glow is identical in use and all other respects to regular Shellawax. It is applied in the same way and has all the same properties. It can also be mixed with Shellawax Cream as an extender and thinner and can be used over EEE-Ultra Shine.

This polish may darken white woods ever so slightly, so it is a good idea to try it on a scrap piece first to make sure it doesn't darken more than you want.

USING SHELLAWAX CREAM AS A SHELLAWAX GLOW EXTENDER Shellawax Glow can be mixed with Shellawax Cream as an extender. This allows for better use of these products on large turned work and for hand rubbed work. For bowls over (6”) 150mm diam, mix the Cream and Shellawax Glow at the rate of approx 50/50 this will give you a runny cream that will stay on the surface longer and allow you more time to work it into the timber.

Use different mixing rates for various jobs 20% Cream to 80% Shellawax Glow for large platters etc up to 900mm (3’) diam and larger.

SHELLAWAX GLOW AS A THINNER Use Shellawax as a thinner for Shellawax Cream, which often thickens with use. This will also extend the life of the Cream. The slight colour difference will not effect the colour of Cream when used.

-

Shellawax cream is a woodturners friction and buffing polish. Sharing many of the characteristics of Shellawax liquid, Shellawax Cream is specially formulated for use on larger turned projects where it would normally be impossible to get a first class finish using a conventional friction polish and on stand-alone articles such as carvings. As with Shellawax, only one application is required to completely finish the work. Made using a specially formulated hard shellac as a base, this excellent product gives a hard, durable finish, with impressive resistance to marks and blemishes from water, alcohol and heat. The cream formulation retards the frictional drying characteristic of friction polishes, making it suitable for use on larger lathe-turned items such as bowls and platters. Being a cream, this product is easily controlled in application and is very economical in use. Shellawax Cream is non-toxic.

Shellawax cream is a woodturners friction and buffing polish. Sharing many of the characteristics of Shellawax liquid, Shellawax Cream is specially formulated for use on larger turned projects where it would normally be impossible to get a first class finish using a conventional friction polish and on stand-alone articles such as carvings. As with Shellawax, only one application is required to completely finish the work. Made using a specially formulated hard shellac as a base, this excellent product gives a hard, durable finish, with impressive resistance to marks and blemishes from water, alcohol and heat. The cream formulation retards the frictional drying characteristic of friction polishes, making it suitable for use on larger lathe-turned items such as bowls and platters. Being a cream, this product is easily controlled in application and is very economical in use. Shellawax Cream is non-toxic.

-

Ever wished you had a finish that was as easy to use as shellac but with the durability of polyurethane? Well wish no more, because here it is.

This unique Hardened Shellac creates a film with a high resistance to heat, water and alcohol, yet it is used in exactly the same was as any normal shellac. It can be applied with a rubber as French polish, brushed, sprayed and dipped.

HOW IS THIS POSSIBLE? After shellac has been dissolved in ethanol* it is possible to introduce additives that cause the shellac to cross link after it has dried. This cross linking takes about 20 days to completely cure, less in hot weather.

USES: Ideal for table tops and other horizontal surfaces such as dresser and desk tops, etc. Also brilliant for use on guitars, lutes, harps and many other musical instruments where a traditional finish is required and good resonance qualities are essential.

NEW IMPROVED FORMULA In February 2009 U-beaut began adding a plasticiser to Hard Shellac. This gives elasticity to the cured finish, to combat crazing on the thin walls of musical instruments, whilst still having the same high resistance to marking from water, alcohol and heat it has always had.

-

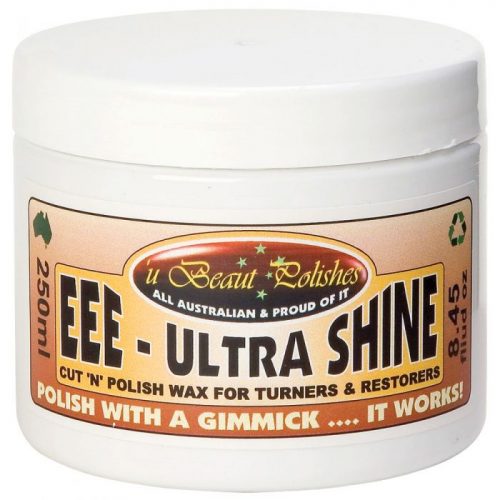

This amazing product is a cut and polish paste containing Tripoli powder, an ultra-fine abrasive. The polish is designed to be used in conjunction with Shellawax Cream and liquid formulations or as a finish in its own right on plastics (such as acrylic, resin-impregnated burr, crushed velvet, artificial ivory and similar products used for pen bodies). It can also be used after French polishing and restorers will find it useful to cut and revive previously polished surfaces. Although designed to be used directly on raw timber, bear in mind that EEE is not a finish in itself and the polished surface will need protecting by the use of some other product (such as Shellawax). EEE-Ultra Shine can be used over many other finishes such as oils and most types of varnish, enhancing the surface and giving it a smoothness and lustre with an ease that you would never have thought possible.

This amazing product is a cut and polish paste containing Tripoli powder, an ultra-fine abrasive. The polish is designed to be used in conjunction with Shellawax Cream and liquid formulations or as a finish in its own right on plastics (such as acrylic, resin-impregnated burr, crushed velvet, artificial ivory and similar products used for pen bodies). It can also be used after French polishing and restorers will find it useful to cut and revive previously polished surfaces. Although designed to be used directly on raw timber, bear in mind that EEE is not a finish in itself and the polished surface will need protecting by the use of some other product (such as Shellawax). EEE-Ultra Shine can be used over many other finishes such as oils and most types of varnish, enhancing the surface and giving it a smoothness and lustre with an ease that you would never have thought possible.

-

This is an oil type finish similar to Danish oil but nothing like it. This product is designed to be hand rubbed on to raw timber, giving a finish with a hard, bright, high gloss. It will bring out amazing depth and brilliance to most timbers making the grain pop and become opalescent, vibrant, shimmering and alive. Especially when used on a fine grained, highly figure timber. And if that's not enough it does it all in a matter of minutes.

Aussie Oil is ideal for use on most small items like pendants, brooches, earrings, small turned items that cannot be fully finished on the lathe. Pens, magnifying glass handles, compacts, key rings, letter openers, in fact almost anything made of wood you can comfortably hold in your hand to polish.

As an extra added bonus, it also works brilliantly as a friction polish on the lathe.

-

High strength waterproof glue specially formulated for multi-purpose applications. In addition to its superior wood-to-wood performance, it is equally effective for metal, ceramic, plastic, Corian, stone and other porous/non-porous materials. Ready to use, offering excellent sandability and unaffected by finishes. Thicker than traditional polyurethanes it provides a non-running, non-drip glue line for more precise applications. Polyurethane glues cure by moisture and an effervescence is a by-product of this, there is no strength in this and it is easily sanded off when dry, the glue will not become brittle with age and will not expand or contract in the joint. In very dry timber it may be necessary to moisten one surface to encourage curing to take place.

High strength waterproof glue specially formulated for multi-purpose applications. In addition to its superior wood-to-wood performance, it is equally effective for metal, ceramic, plastic, Corian, stone and other porous/non-porous materials. Ready to use, offering excellent sandability and unaffected by finishes. Thicker than traditional polyurethanes it provides a non-running, non-drip glue line for more precise applications. Polyurethane glues cure by moisture and an effervescence is a by-product of this, there is no strength in this and it is easily sanded off when dry, the glue will not become brittle with age and will not expand or contract in the joint. In very dry timber it may be necessary to moisten one surface to encourage curing to take place. -

Worktop Oil is a unique water-borne blend of natural plant oils and other special ingredients which nourishes and protects all types of timber. It is a quick-drying wooden work surface treatment, leaving a durable and water-resistant seal which is not vulnerable to scratching or chipping. Plant oils used in its formulation originate from sustainable sources. One litre will cover around 13 square metres per coat depending on the absorbency of the wood.

Worktop Oil is a unique water-borne blend of natural plant oils and other special ingredients which nourishes and protects all types of timber. It is a quick-drying wooden work surface treatment, leaving a durable and water-resistant seal which is not vulnerable to scratching or chipping. Plant oils used in its formulation originate from sustainable sources. One litre will cover around 13 square metres per coat depending on the absorbency of the wood.- Water based & quick drying

- For all solid wood worktops

- Low odour

- Food safe

- Natural finish

-

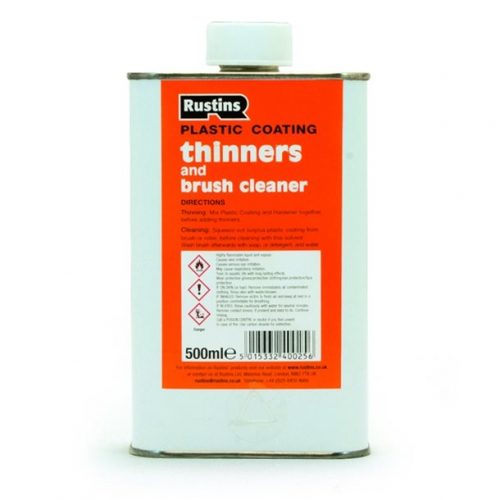

Two-part clear cold cure lacquer for use on wood, hardboard, cork and plastic laminates. Extremely good adhesion, resistant to heat, solvents and abrasion. Can be burnished to a mirror like gloss or rubbed down to a smooth, satin finish with steel wool and wax. An excellent finish for marquetry as it does not darken light coloured veneers and does not yellow or craze on ageing. Hard-dry within 2 hours of application. Plastic Coating conforms to The Articles in Contact with Food Regulations.

Two-part clear cold cure lacquer for use on wood, hardboard, cork and plastic laminates. Extremely good adhesion, resistant to heat, solvents and abrasion. Can be burnished to a mirror like gloss or rubbed down to a smooth, satin finish with steel wool and wax. An excellent finish for marquetry as it does not darken light coloured veneers and does not yellow or craze on ageing. Hard-dry within 2 hours of application. Plastic Coating conforms to The Articles in Contact with Food Regulations.

-

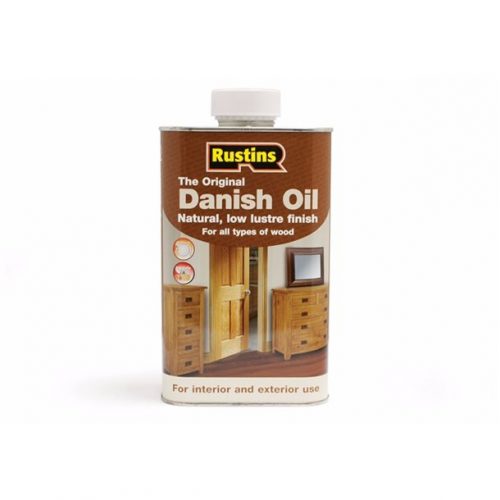

A unique formulation developed by Rustins that is suitable for all types of wood. It differs from Teak Oil in that it contains special ingredients to give it a low lustre finish. It is an easy to use wipe on finish, which brings out the beauty of the timber and gives a natural, open grained, soft lustrous finish. Ideal for all woods and is excellent on turned woodwork. Danish Oil conforms to The Articles in Contact with Food Regulations and to the Toys (Safety) Regulations 1995, BS:EN71 Part 3.

A unique formulation developed by Rustins that is suitable for all types of wood. It differs from Teak Oil in that it contains special ingredients to give it a low lustre finish. It is an easy to use wipe on finish, which brings out the beauty of the timber and gives a natural, open grained, soft lustrous finish. Ideal for all woods and is excellent on turned woodwork. Danish Oil conforms to The Articles in Contact with Food Regulations and to the Toys (Safety) Regulations 1995, BS:EN71 Part 3.

-

A blend of natural plant oils to nourish and protect chopping boards and worktops. It penetrates the wood with no surface film to chip. It has a clear finish to enhance the natural beauty of wood. The Oil contains anti-microbial additives with a slow release formula which provide protection against a wide range of bacteria including E-coli and MRSA. Rustins Chopping Board Oil conforms to The Articles in Contact with Food Regulations.

A blend of natural plant oils to nourish and protect chopping boards and worktops. It penetrates the wood with no surface film to chip. It has a clear finish to enhance the natural beauty of wood. The Oil contains anti-microbial additives with a slow release formula which provide protection against a wide range of bacteria including E-coli and MRSA. Rustins Chopping Board Oil conforms to The Articles in Contact with Food Regulations. -

The Sandmaster is an essential part of every turner's tool kit. It comes with 5 different grits of abrasive to take even the roughest projects to a glass-like finish every time. It avoids an uneven finish often associated with hand sanding and there is no danger of catching hands on the revolving project. There is little or no surface damage/head build-up, as there is with power sanding and there is no cable to trip over. Head articulates to access even the most difficult areas. Sponge head is ideal for working in tight spaces. Sandmaster creates a fraction of the dust generated by power sanding. It can be adapted to take a polishing mop.

The Sandmaster is an essential part of every turner's tool kit. It comes with 5 different grits of abrasive to take even the roughest projects to a glass-like finish every time. It avoids an uneven finish often associated with hand sanding and there is no danger of catching hands on the revolving project. There is little or no surface damage/head build-up, as there is with power sanding and there is no cable to trip over. Head articulates to access even the most difficult areas. Sponge head is ideal for working in tight spaces. Sandmaster creates a fraction of the dust generated by power sanding. It can be adapted to take a polishing mop. -

Sale!

The Record 8" Buffing Machine is the ideal solution for buffing and polishing woods as well as some metals and can be used in conjunction with pastes and compounds on a wide range of surfaces. It features a heavy-duty cast iron base which can be bolted to a bench and rubber feet to reduce vibration, making for smooth and stable running. The machine is supplied with two high-quality 8” (200 mm) diameter fine buffing wheels to ensure an excellent finish is achieved.

The Record 8" Buffing Machine is the ideal solution for buffing and polishing woods as well as some metals and can be used in conjunction with pastes and compounds on a wide range of surfaces. It features a heavy-duty cast iron base which can be bolted to a bench and rubber feet to reduce vibration, making for smooth and stable running. The machine is supplied with two high-quality 8” (200 mm) diameter fine buffing wheels to ensure an excellent finish is achieved. -

Out of stock

While this resin has been manufactured to resist scratching and resistance to marking from heat sources we must stress this resin will still mark if sharp items are moved across the surface or hot items are placed on the surface.

As with all casting products, we stress that customers should purchase a small amount to perform initial tests to ensure suitability for their project and requirements.

Pigmentation Epoxy pigments are the recommended system to colour this resin however the polyester range of pigments will also work. Please read the Technical and Safety Data sheets prior to use. We recommend small scale testing to ensure compatibility before using at full scale. Cold Weather Notice Cooler temperatures in the UK and Ireland around mid-autumn to mid spring are not ideal conditions for water clear epoxy systems, this can increase the chances of crystallisation in the resin (this can occur at room temperature depending on circumstances, it is however much less common). Appearance can differ depending on the degree of crystallisation, from small lumps sitting on the surface to a hazy/milky white appearance, extreme cases the contents may completely solidify. Crystallisation occurs due to a phase change from liquid or solid similar to that of water turning to ice, fortunately it is easily reversed by warming the epoxy component to 60°c. Ensure any crystals are completely removed as remaining crystals can act as a seed causing the crystals to form again quite quickly. Lab results show the heating cycle to remove crystals can be repeated on multiple occasions before beginning to suffer from any losses in resin properties. We recommend keeping the resin system at a good room temperature at all times where possible, ensure to clean the lids and bottle necks of containers with isopropyl alcohol / acetone allowing the solvent to evaporate before replacing the lid.Product Data Units Mix Mix Ratio Weight 100 : 50 Hardness ShoreD 80 - 85 Viscosity (25°C) mPa.s 600 - 900 Density (25°C) g/cm3 1.09 – 1.13 Pot life (200g, 25°C) Mins 25 - 30 Cure Time (200g, 25°C) Hours 24 Full Cure (25°C) Days 7 Recommended Casting Thickness mm 1 - 5 -

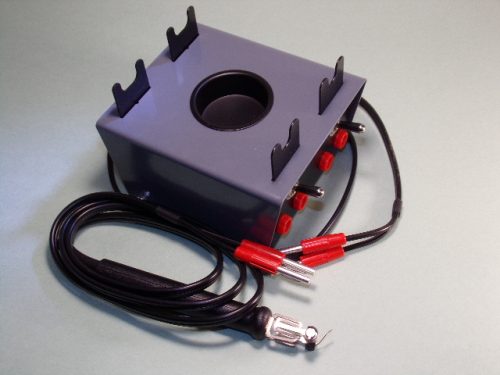

- Designed for use with the Peter Child Pyrography machine: two pen flexibility at the flick of a switch.

-

Features:

Features:- Fine control of heat and precise handling of the burning head, variable heat, up to 1100º C.

- The pen (for handpiece) has a cool running and lightweight handle which remains comfortable even after many hours of use.

- Writes quickly and as fluently as a fountain pen.

- Cost effective replacement points.

- The ability to shape your own points from specialist wire with the supplied fine wire, perfect for fine detailed burning. Thicker wire is available, ideal for enhancing bird or stick carving.

-

A penetrative, nourishing, quality finishing oil which reflects the original, heavy-oil formulations that traditional Danish Oils were renowned for. As a clear finish will richly enhance the existing woodcolour/s. For best results, requires quality dry-sand surface preparation; using 600 /1200 / 1500 grit papers (the finer the better) Upon curing/drying (min. 14 days) makes for ideally prepared surface for further (optional) Waxing/Polishing.

A penetrative, nourishing, quality finishing oil which reflects the original, heavy-oil formulations that traditional Danish Oils were renowned for. As a clear finish will richly enhance the existing woodcolour/s. For best results, requires quality dry-sand surface preparation; using 600 /1200 / 1500 grit papers (the finer the better) Upon curing/drying (min. 14 days) makes for ideally prepared surface for further (optional) Waxing/Polishing.