-

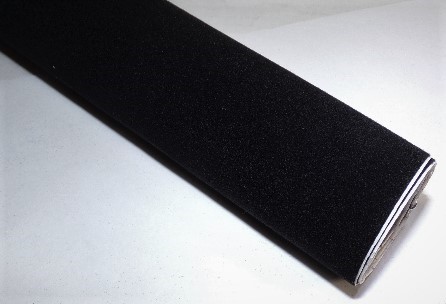

1" x 20' abrasive in a convenient dispenser. Perfect for spindle, pen, or any turning where small strips are needed. This convenient dispenser is loaded with four or 1" x 20' rolls of cloth backed aluminum oxide abrasive. Each dispenser pack contains one roll of 150, 240, 320 & 400 grit abrasive. Just pull out and tear off the length of abrasive strip you need.

1" x 20' abrasive in a convenient dispenser. Perfect for spindle, pen, or any turning where small strips are needed. This convenient dispenser is loaded with four or 1" x 20' rolls of cloth backed aluminum oxide abrasive. Each dispenser pack contains one roll of 150, 240, 320 & 400 grit abrasive. Just pull out and tear off the length of abrasive strip you need. -

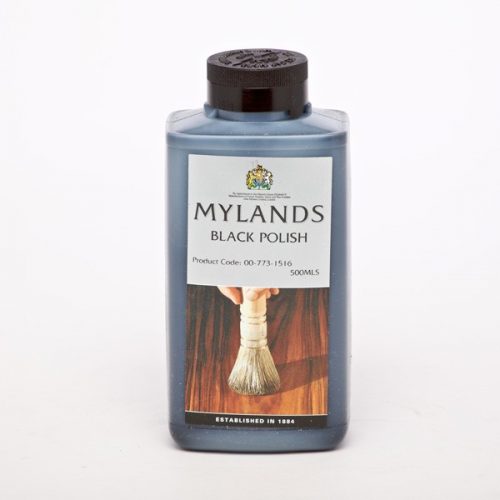

Although French polish is the general term for all types of Shellac Polish, it is also a product in its own right. Mylands range contains many blends of Shellac Polish which have been developed over the years to fulfil various different requirements – some of which are slightly modified products for a specific purpose. They come in various depths of colour, which give the French Polisher latitude to choose the most appropriate product for the timber being polished. Shellac products have a variety of uses from finishing antiques and reproduction furniture to acting as a barrier between two normally incompatible finishes. They are particularly useful when refurbishing furniture as they will seal in any wax product which may have been applied to the furniture in the past.

Although French polish is the general term for all types of Shellac Polish, it is also a product in its own right. Mylands range contains many blends of Shellac Polish which have been developed over the years to fulfil various different requirements – some of which are slightly modified products for a specific purpose. They come in various depths of colour, which give the French Polisher latitude to choose the most appropriate product for the timber being polished. Shellac products have a variety of uses from finishing antiques and reproduction furniture to acting as a barrier between two normally incompatible finishes. They are particularly useful when refurbishing furniture as they will seal in any wax product which may have been applied to the furniture in the past.

-

Fine finishing starts with good preparation! Use these mildly abrasive pads after sanding for that final smoothing process to give a near-perfect surface prior to applying any finish. Very long lasting, these pads are also very flexible and do not crumble, thus avoiding any fear of contamination of your work. Exercise care when using these pads with the lathe revolving.

Fine finishing starts with good preparation! Use these mildly abrasive pads after sanding for that final smoothing process to give a near-perfect surface prior to applying any finish. Very long lasting, these pads are also very flexible and do not crumble, thus avoiding any fear of contamination of your work. Exercise care when using these pads with the lathe revolving. -

A low sheen finishing oil based on Tung Nut Oil, Beeswax, Citrus solvents and anti-fungal oils that penetrates the timber substrate to nourish, preserve and seal; as well as providing protection against weather degradation and rot. A natural alternative to petroleum hydrocarbons and water based oils

A low sheen finishing oil based on Tung Nut Oil, Beeswax, Citrus solvents and anti-fungal oils that penetrates the timber substrate to nourish, preserve and seal; as well as providing protection against weather degradation and rot. A natural alternative to petroleum hydrocarbons and water based oils -

Organoils Hi-Speed Finishing Oils specifically formulated for on-lathe, under-turning-speed finishing. It is a heavy oil which can well deal with the load (fill) requirements of softwoods - you may choose to cut it (with vegetable turpentine) for denser hardwoods. One of its unique ingredients is the rare, Mustard Seed Oil (a well kept Aussie secret until now!) which gives the formulation good slip for the wet-sanding procedure and a silken touch to the finished result.

-

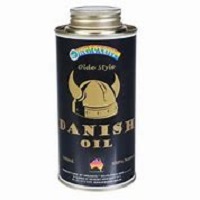

A penetrative, nourishing, quality finishing oil which reflects the original, heavy-oil formulations that traditional Danish Oils were renowned for. As a clear finish will richly enhance the existing woodcolour/s. For best results, requires quality dry-sand surface preparation; using 600 /1200 / 1500 grit papers (the finer the better) Upon curing/drying (min. 14 days) makes for ideally prepared surface for further (optional) Waxing/Polishing.

A penetrative, nourishing, quality finishing oil which reflects the original, heavy-oil formulations that traditional Danish Oils were renowned for. As a clear finish will richly enhance the existing woodcolour/s. For best results, requires quality dry-sand surface preparation; using 600 /1200 / 1500 grit papers (the finer the better) Upon curing/drying (min. 14 days) makes for ideally prepared surface for further (optional) Waxing/Polishing. -

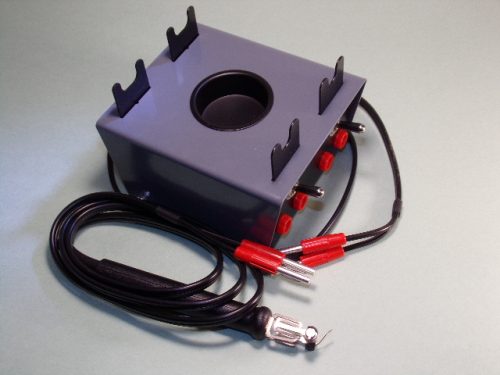

Features:

Features:- Fine control of heat and precise handling of the burning head, variable heat, up to 1100º C.

- The pen (for handpiece) has a cool running and lightweight handle which remains comfortable even after many hours of use.

- Writes quickly and as fluently as a fountain pen.

- Cost effective replacement points.

- The ability to shape your own points from specialist wire with the supplied fine wire, perfect for fine detailed burning. Thicker wire is available, ideal for enhancing bird or stick carving.

-

- Designed for use with the Peter Child Pyrography machine: two pen flexibility at the flick of a switch.

-

Out of stock

While this resin has been manufactured to resist scratching and resistance to marking from heat sources we must stress this resin will still mark if sharp items are moved across the surface or hot items are placed on the surface.

As with all casting products, we stress that customers should purchase a small amount to perform initial tests to ensure suitability for their project and requirements.

Pigmentation Epoxy pigments are the recommended system to colour this resin however the polyester range of pigments will also work. Please read the Technical and Safety Data sheets prior to use. We recommend small scale testing to ensure compatibility before using at full scale. Cold Weather Notice Cooler temperatures in the UK and Ireland around mid-autumn to mid spring are not ideal conditions for water clear epoxy systems, this can increase the chances of crystallisation in the resin (this can occur at room temperature depending on circumstances, it is however much less common). Appearance can differ depending on the degree of crystallisation, from small lumps sitting on the surface to a hazy/milky white appearance, extreme cases the contents may completely solidify. Crystallisation occurs due to a phase change from liquid or solid similar to that of water turning to ice, fortunately it is easily reversed by warming the epoxy component to 60°c. Ensure any crystals are completely removed as remaining crystals can act as a seed causing the crystals to form again quite quickly. Lab results show the heating cycle to remove crystals can be repeated on multiple occasions before beginning to suffer from any losses in resin properties. We recommend keeping the resin system at a good room temperature at all times where possible, ensure to clean the lids and bottle necks of containers with isopropyl alcohol / acetone allowing the solvent to evaporate before replacing the lid.Product Data Units Mix Mix Ratio Weight 100 : 50 Hardness ShoreD 80 - 85 Viscosity (25°C) mPa.s 600 - 900 Density (25°C) g/cm3 1.09 – 1.13 Pot life (200g, 25°C) Mins 25 - 30 Cure Time (200g, 25°C) Hours 24 Full Cure (25°C) Days 7 Recommended Casting Thickness mm 1 - 5 -

Sale!Out of stock

The Record 8" Buffing Machine is the ideal solution for buffing and polishing woods as well as some metals and can be used in conjunction with pastes and compounds on a wide range of surfaces. It features a heavy-duty cast iron base which can be bolted to a bench and rubber feet to reduce vibration, making for smooth and stable running. The machine is supplied with two high-quality 8” (200 mm) diameter fine buffing wheels to ensure an excellent finish is achieved.

The Record 8" Buffing Machine is the ideal solution for buffing and polishing woods as well as some metals and can be used in conjunction with pastes and compounds on a wide range of surfaces. It features a heavy-duty cast iron base which can be bolted to a bench and rubber feet to reduce vibration, making for smooth and stable running. The machine is supplied with two high-quality 8” (200 mm) diameter fine buffing wheels to ensure an excellent finish is achieved. -

The Sandmaster is an essential part of every turner's tool kit. It comes with 5 different grits of abrasive to take even the roughest projects to a glass-like finish every time. It avoids an uneven finish often associated with hand sanding and there is no danger of catching hands on the revolving project. There is little or no surface damage/head build-up, as there is with power sanding and there is no cable to trip over. Head articulates to access even the most difficult areas. Sponge head is ideal for working in tight spaces. Sandmaster creates a fraction of the dust generated by power sanding. It can be adapted to take a polishing mop.

The Sandmaster is an essential part of every turner's tool kit. It comes with 5 different grits of abrasive to take even the roughest projects to a glass-like finish every time. It avoids an uneven finish often associated with hand sanding and there is no danger of catching hands on the revolving project. There is little or no surface damage/head build-up, as there is with power sanding and there is no cable to trip over. Head articulates to access even the most difficult areas. Sponge head is ideal for working in tight spaces. Sandmaster creates a fraction of the dust generated by power sanding. It can be adapted to take a polishing mop. -

A blend of natural plant oils to nourish and protect chopping boards and worktops. It penetrates the wood with no surface film to chip. It has a clear finish to enhance the natural beauty of wood. The Oil contains anti-microbial additives with a slow release formula which provide protection against a wide range of bacteria including E-coli and MRSA. Rustins Chopping Board Oil conforms to The Articles in Contact with Food Regulations.

A blend of natural plant oils to nourish and protect chopping boards and worktops. It penetrates the wood with no surface film to chip. It has a clear finish to enhance the natural beauty of wood. The Oil contains anti-microbial additives with a slow release formula which provide protection against a wide range of bacteria including E-coli and MRSA. Rustins Chopping Board Oil conforms to The Articles in Contact with Food Regulations. -

A unique formulation developed by Rustins that is suitable for all types of wood. It differs from Teak Oil in that it contains special ingredients to give it a low lustre finish. It is an easy to use wipe on finish, which brings out the beauty of the timber and gives a natural, open grained, soft lustrous finish. Ideal for all woods and is excellent on turned woodwork. Danish Oil conforms to The Articles in Contact with Food Regulations and to the Toys (Safety) Regulations 1995, BS:EN71 Part 3.

A unique formulation developed by Rustins that is suitable for all types of wood. It differs from Teak Oil in that it contains special ingredients to give it a low lustre finish. It is an easy to use wipe on finish, which brings out the beauty of the timber and gives a natural, open grained, soft lustrous finish. Ideal for all woods and is excellent on turned woodwork. Danish Oil conforms to The Articles in Contact with Food Regulations and to the Toys (Safety) Regulations 1995, BS:EN71 Part 3.

-

Worktop Oil is a unique water-borne blend of natural plant oils and other special ingredients which nourishes and protects all types of timber. It is a quick-drying wooden work surface treatment, leaving a durable and water-resistant seal which is not vulnerable to scratching or chipping. Plant oils used in its formulation originate from sustainable sources. One litre will cover around 13 square metres per coat depending on the absorbency of the wood.

Worktop Oil is a unique water-borne blend of natural plant oils and other special ingredients which nourishes and protects all types of timber. It is a quick-drying wooden work surface treatment, leaving a durable and water-resistant seal which is not vulnerable to scratching or chipping. Plant oils used in its formulation originate from sustainable sources. One litre will cover around 13 square metres per coat depending on the absorbency of the wood.- Water based & quick drying

- For all solid wood worktops

- Low odour

- Food safe

- Natural finish

-

Out of stock

he waterproof formula provides superior bond strength, longer open assembly time and lower application temperature.

he waterproof formula provides superior bond strength, longer open assembly time and lower application temperature. -

Out of stock

Interior use only, initial tack time 30 mins, setting time 24 hours approximately. Open time 5 minutes, assembly time 10-15 minutes, shelf life 12 months (kept airtight).

Interior use only, initial tack time 30 mins, setting time 24 hours approximately. Open time 5 minutes, assembly time 10-15 minutes, shelf life 12 months (kept airtight).