-

This amazing product is a cut and polish paste containing Tripoli powder, an ultra-fine abrasive. The polish is designed to be used in conjunction with Shellawax Cream and liquid formulations or as a finish in its own right on plastics (such as acrylic, resin-impregnated burr, crushed velvet, artificial ivory and similar products used for pen bodies). It can also be used after French polishing and restorers will find it useful to cut and revive previously polished surfaces. Although designed to be used directly on raw timber, bear in mind that EEE is not a finish in itself and the polished surface will need protecting by the use of some other product (such as Shellawax). EEE-Ultra Shine can be used over many other finishes such as oils and most types of varnish, enhancing the surface and giving it a smoothness and lustre with an ease that you would never have thought possible.

This amazing product is a cut and polish paste containing Tripoli powder, an ultra-fine abrasive. The polish is designed to be used in conjunction with Shellawax Cream and liquid formulations or as a finish in its own right on plastics (such as acrylic, resin-impregnated burr, crushed velvet, artificial ivory and similar products used for pen bodies). It can also be used after French polishing and restorers will find it useful to cut and revive previously polished surfaces. Although designed to be used directly on raw timber, bear in mind that EEE is not a finish in itself and the polished surface will need protecting by the use of some other product (such as Shellawax). EEE-Ultra Shine can be used over many other finishes such as oils and most types of varnish, enhancing the surface and giving it a smoothness and lustre with an ease that you would never have thought possible.

-

Good finishing requires a good foundation, and Cellulose Sanding Sealer is probably the best way of providing one. Compatible with everything in the Chestnut Products range that benefits from the use of a sanding sealer (which is pretty much everything apart from oil finishes!) it is superbly universal.

The purpose of a sanding sealer is manifold.

Good finishing requires a good foundation, and Cellulose Sanding Sealer is probably the best way of providing one. Compatible with everything in the Chestnut Products range that benefits from the use of a sanding sealer (which is pretty much everything apart from oil finishes!) it is superbly universal.

The purpose of a sanding sealer is manifold.

- It seals the open pores of the timber prior to the application of the next coat, meaning that more of it stays on the surface and less of the finish is needed. Not only does this make it economical, when finishing the thinner the applied coat the less likely it is to get damaged, so a sanding sealer will help the top coats be more resilient.

- Sanding Sealers also bind the loose fibres of the timber together giving a more solid foundation for the next coat, which helps make sure the final finish is able to adhere properly and thus be more durable.

- They also include a sanding agent which acts as a lubricant to make the sanding process easier – the sanding agent also stands slightly proud of the surface of the sealer and it is this that is denibbed – the sealer itself should still be intact after sanding.

-

A one-application woodturners friction polish that really does work and is ideal for use on smaller spindle work such as pens and similar objects up to around 10 cm (4") diameter. This exceptional polish is made using a specially formulated hard shellac as a base to give a harder, more durable finish, giving greater resistance to marks and blemishes from water, alcohol and heat. Normally applied directly onto bare timber (though it can be used over most oils too – but test on scrap first) this polish dries almost instantly yet goes on hardening for up to three weeks resulting in a truly durable finish which far exceeds others on the market today. Once fully cured the finish is food-safe and non-toxic.

A one-application woodturners friction polish that really does work and is ideal for use on smaller spindle work such as pens and similar objects up to around 10 cm (4") diameter. This exceptional polish is made using a specially formulated hard shellac as a base to give a harder, more durable finish, giving greater resistance to marks and blemishes from water, alcohol and heat. Normally applied directly onto bare timber (though it can be used over most oils too – but test on scrap first) this polish dries almost instantly yet goes on hardening for up to three weeks resulting in a truly durable finish which far exceeds others on the market today. Once fully cured the finish is food-safe and non-toxic.

-

Woodturners stick wax is a mixture of beeswax and carnauba wax it is slightly softer than the Carnauba Wax Stick and therefore slightly easier to apply and there are no concerns about it marking softer woods. Applied over a sanding sealer, simply hold the stick against the revolving work and allow the heat generated to melt the wax onto the wood. Buff up straight away using Safety Cloth, using the cloth to ensure an even coating.

Woodturners stick wax is a mixture of beeswax and carnauba wax it is slightly softer than the Carnauba Wax Stick and therefore slightly easier to apply and there are no concerns about it marking softer woods. Applied over a sanding sealer, simply hold the stick against the revolving work and allow the heat generated to melt the wax onto the wood. Buff up straight away using Safety Cloth, using the cloth to ensure an even coating. -

Shellawax cream is a woodturners friction and buffing polish. Sharing many of the characteristics of Shellawax liquid, Shellawax Cream is specially formulated for use on larger turned projects where it would normally be impossible to get a first class finish using a conventional friction polish and on stand-alone articles such as carvings. As with Shellawax, only one application is required to completely finish the work. Made using a specially formulated hard shellac as a base, this excellent product gives a hard, durable finish, with impressive resistance to marks and blemishes from water, alcohol and heat. The cream formulation retards the frictional drying characteristic of friction polishes, making it suitable for use on larger lathe-turned items such as bowls and platters. Being a cream, this product is easily controlled in application and is very economical in use. Shellawax Cream is non-toxic.

Shellawax cream is a woodturners friction and buffing polish. Sharing many of the characteristics of Shellawax liquid, Shellawax Cream is specially formulated for use on larger turned projects where it would normally be impossible to get a first class finish using a conventional friction polish and on stand-alone articles such as carvings. As with Shellawax, only one application is required to completely finish the work. Made using a specially formulated hard shellac as a base, this excellent product gives a hard, durable finish, with impressive resistance to marks and blemishes from water, alcohol and heat. The cream formulation retards the frictional drying characteristic of friction polishes, making it suitable for use on larger lathe-turned items such as bowls and platters. Being a cream, this product is easily controlled in application and is very economical in use. Shellawax Cream is non-toxic.

-

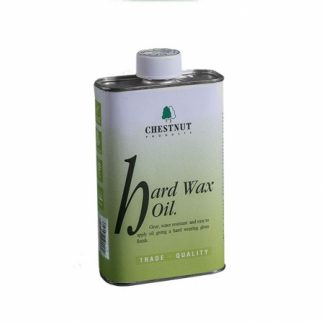

If you’re looking for a clear finish that is tough, hardwearing and gives a satin lustre yet is still very easy to apply, even on larger areas, you’re in the right place.

Hard Wax Oil is a particular blend of tough oils combined with special waxes which dries to an exceptionally resilient finish. Ideal for anything that is going to be subjected to water splashes or a lot of handling this oil may not be indestructible but it will stand up to a lot of abuse.

It retains the ease of application typical of an oil and it stays wet long enough to get a smooth, even finish – even on large areas – but is touch dry and tack free in about 20 minutes, and better yet is ready for a second coat after about four hours (in normal conditions).

Hard Wax Oil will build to a bright gloss finish after 2-3 coats. Rub down lightly between coats with a fine abrasive. Once hard dry (allow at least 24 hours) it can be brought to an even brighter shine using either the buffing wheel system or burnishing cream.

For a not-quite-so-bright finish use a mild abrasive to reduce the gloss. For best results lubricate the abrasive with microcrystalline wax to retain the toughness of the oil.

If you’re looking for a clear finish that is tough, hardwearing and gives a satin lustre yet is still very easy to apply, even on larger areas, you’re in the right place.

Hard Wax Oil is a particular blend of tough oils combined with special waxes which dries to an exceptionally resilient finish. Ideal for anything that is going to be subjected to water splashes or a lot of handling this oil may not be indestructible but it will stand up to a lot of abuse.

It retains the ease of application typical of an oil and it stays wet long enough to get a smooth, even finish – even on large areas – but is touch dry and tack free in about 20 minutes, and better yet is ready for a second coat after about four hours (in normal conditions).

Hard Wax Oil will build to a bright gloss finish after 2-3 coats. Rub down lightly between coats with a fine abrasive. Once hard dry (allow at least 24 hours) it can be brought to an even brighter shine using either the buffing wheel system or burnishing cream.

For a not-quite-so-bright finish use a mild abrasive to reduce the gloss. For best results lubricate the abrasive with microcrystalline wax to retain the toughness of the oil.

-

This is a solid block of carnauba wax, popular with woodturners. It gives a bright gloss finish and is also very hard wearing, able to withstand a medium amount of handling without showing finger marks. Apply over a sanding sealer by holding it against your work at it revolves on the lathe. Do not press too much – the wax is very hard and can scratch softer woods – the idea is to generate enough heat for the wax to melt slightly and transfer onto the wood. (This is easier than it sounds!). Use sparingly, and use the polishing process (using safety cloth) to ensure the wax is spread evenly. Buffing will produce a high gloss finish.

This is a solid block of carnauba wax, popular with woodturners. It gives a bright gloss finish and is also very hard wearing, able to withstand a medium amount of handling without showing finger marks. Apply over a sanding sealer by holding it against your work at it revolves on the lathe. Do not press too much – the wax is very hard and can scratch softer woods – the idea is to generate enough heat for the wax to melt slightly and transfer onto the wood. (This is easier than it sounds!). Use sparingly, and use the polishing process (using safety cloth) to ensure the wax is spread evenly. Buffing will produce a high gloss finish. -

An exciting and vibrant set of colours for staining wood, Spirit Stains are methanol based to make them quick drying and because of this they also will not raise the grain of the timber they are applied to. The pigments used to make this stains are of the highest quality and all score the top ratings of 7s and 8s in the Blue Wool Scale, the measuring system used to rate fade resistance. This means you can use them with confidence knowing that the colour you apply will still be the same many years later. Spirit Stains are fully inter-mixable so you can produce virtually any colour you can think of, giving you full opportunity to be as creative as you wish. The colours will also mix after application so you can blend from one colour to another for fantastic ‘flare’ effects. Spirit Stain White is designed primarily as a mixer to create pastel shades when mixed with other Spirit Stain colours. It can be used to stain timber but as it is a translucent stain this can have a limited effect depending on the base colour of the timber used. Should you want a more subtle colour you can dilute the stains with Spirit Thinners for a delicate wash effect.

An exciting and vibrant set of colours for staining wood, Spirit Stains are methanol based to make them quick drying and because of this they also will not raise the grain of the timber they are applied to. The pigments used to make this stains are of the highest quality and all score the top ratings of 7s and 8s in the Blue Wool Scale, the measuring system used to rate fade resistance. This means you can use them with confidence knowing that the colour you apply will still be the same many years later. Spirit Stains are fully inter-mixable so you can produce virtually any colour you can think of, giving you full opportunity to be as creative as you wish. The colours will also mix after application so you can blend from one colour to another for fantastic ‘flare’ effects. Spirit Stain White is designed primarily as a mixer to create pastel shades when mixed with other Spirit Stain colours. It can be used to stain timber but as it is a translucent stain this can have a limited effect depending on the base colour of the timber used. Should you want a more subtle colour you can dilute the stains with Spirit Thinners for a delicate wash effect.

-

As the name suggests, the High Gloss variation brings a higher shine to your decorative woodwork . It is tough, with an additional 'Pow' of shine that suits some lathe projects. Contains a high quantity of carnauba and microcrystalline waxes. Shiny, tough and exceptionally long lasting. Food and toy safe, too. Supplied in 130g tins.

As the name suggests, the High Gloss variation brings a higher shine to your decorative woodwork . It is tough, with an additional 'Pow' of shine that suits some lathe projects. Contains a high quantity of carnauba and microcrystalline waxes. Shiny, tough and exceptionally long lasting. Food and toy safe, too. Supplied in 130g tins. -

This pure cellulose solvent is a high quality dilutant for our cellulose based products, such as Cellulose Sanding Sealer and Melamine Lacquer. Thinning these products can help to make them easier to apply, especially over larger areas as it helps them flow out. Cellulose Thinners is also useful for cleaning any spills you may have in the workshop and is strong enough to help clean most things, taking care to ensure that it does not attack It can also be used to thin Spirit Stain to give a delicate wash effects, although spirit thinners is the better option for this.

This pure cellulose solvent is a high quality dilutant for our cellulose based products, such as Cellulose Sanding Sealer and Melamine Lacquer. Thinning these products can help to make them easier to apply, especially over larger areas as it helps them flow out. Cellulose Thinners is also useful for cleaning any spills you may have in the workshop and is strong enough to help clean most things, taking care to ensure that it does not attack It can also be used to thin Spirit Stain to give a delicate wash effects, although spirit thinners is the better option for this.

-

- Professional Clear Gloss Lacquer Superb thick, nicely levelling product. Requires fewer coats for a deep, lush shine. Can be mechanically buffed after a few hours.

- Professional Clear Satin Lacquer Produces a superb satin finish on most surfaces in just two coats (over sealer) without further work required.

- Professional Black Gloss Lacquer Like the Clear Gloss, this black requires fewer coats for a fantastic depth of finish.

- Professional Black Satin Lacquer A silky smooth black surface over sealer can be produced in just a couple of coats. Use without sealer to preserve visible grain.

-

Safety Cloth is a thick, non-woven paper cloth. Designed to stay wet longer to assist the transfer of finishes to your chosen surface, it also tears very easily if it gets caught in revolving parts thus avoiding the danger of fingers being dragged into machinery. The texture of Safety Cloth ensures that a thin, even coat is applied and the thickness means that it retains it’s strength and the same piece can be used several times with the same finish. Safety Cloth is not a replacement for common sense and good safety practise.

Safety Cloth is a thick, non-woven paper cloth. Designed to stay wet longer to assist the transfer of finishes to your chosen surface, it also tears very easily if it gets caught in revolving parts thus avoiding the danger of fingers being dragged into machinery. The texture of Safety Cloth ensures that a thin, even coat is applied and the thickness means that it retains it’s strength and the same piece can be used several times with the same finish. Safety Cloth is not a replacement for common sense and good safety practise. -

Friction Polish is a shellac based polish ideal for creating a high gloss finish on or off the lathe. It’s a great decorative finish and is ideal for small items but can be difficult to apply to larger items on the lathe (over about 8 inch diameter). The high amount of shellac in Friction Polish does two main things. Firstly it helps seal bare wood and give it a great shine, which is good. Sadly the price of this commodity shot up a few years ago when the shellac crop failed and it never went back down, meaning that the cost of the polish has also risen sharply. Nevertheless, Friction Polish remains one of the most popular finishes for turners. It can be applied to bare wood but is normally used over a sealer and any of the sealers in the Chestnut Products range are suitable for this. Applied with the lathe running it dries almost instantly and builds to a deep, rich shine very quickly. Avoid using too much as this can cause ‘rings’ to appear on the surface. Friction Polish can be applied off the lathe with great success, using it like a French Polish and rubbing it into the surface. This does require a large amount of elbow grease (sadly not something we supply) but the end result is well worth the effort!

Friction Polish is a shellac based polish ideal for creating a high gloss finish on or off the lathe. It’s a great decorative finish and is ideal for small items but can be difficult to apply to larger items on the lathe (over about 8 inch diameter). The high amount of shellac in Friction Polish does two main things. Firstly it helps seal bare wood and give it a great shine, which is good. Sadly the price of this commodity shot up a few years ago when the shellac crop failed and it never went back down, meaning that the cost of the polish has also risen sharply. Nevertheless, Friction Polish remains one of the most popular finishes for turners. It can be applied to bare wood but is normally used over a sealer and any of the sealers in the Chestnut Products range are suitable for this. Applied with the lathe running it dries almost instantly and builds to a deep, rich shine very quickly. Avoid using too much as this can cause ‘rings’ to appear on the surface. Friction Polish can be applied off the lathe with great success, using it like a French Polish and rubbing it into the surface. This does require a large amount of elbow grease (sadly not something we supply) but the end result is well worth the effort!

-

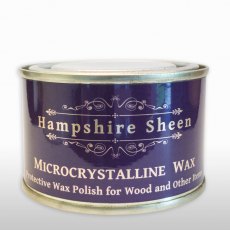

Chestnut Products’ Microcrystalline Wax is a blend of high quality waxes rich in microcrystalline wax – a wax derived from the petroleum refining process and known for the fineness of its crystals.

This is mixed with a special solvent to create a firm wax which, when dry, knits down to form a very dense coating making it very water resistant, meaning that it is ideal for any items that are likely to come into contact with water for short periods of time.

Microcrystalline waxes also have a higher melting point than other waxes traditionally used to make polishing waxes, the benefit of which is that repeated handling of items finished in Microcrystalline Wax won’t finger mark in the same way, as the melting point is higher than normal body temperature.

Microcrystalline Wax should be used over one of the Chestnut Products’ sanding sealers and allowed to dry (about 20 minutes) before buffing to a shine.

For best results apply a very thin coat, spreading the wax evenly over the entire surface.

Microcrystalline Wax can also be used on the buffing wheel system. In this situation use the A and B Wheel as normal, then apply the Microcrystalline Wax to the item you are polishing. Allow 20 minutes for the wax to dry then buff and normal using the C Wheel. You can use the same C Wheel for both Microcrystalline Wax and the Carnuaba Wax Stick.

Microcrystalline Wax has been tested to the EN71 Part 3 regulations regarding coatings used on toys.

Chestnut Products’ Microcrystalline Wax is a blend of high quality waxes rich in microcrystalline wax – a wax derived from the petroleum refining process and known for the fineness of its crystals.

This is mixed with a special solvent to create a firm wax which, when dry, knits down to form a very dense coating making it very water resistant, meaning that it is ideal for any items that are likely to come into contact with water for short periods of time.

Microcrystalline waxes also have a higher melting point than other waxes traditionally used to make polishing waxes, the benefit of which is that repeated handling of items finished in Microcrystalline Wax won’t finger mark in the same way, as the melting point is higher than normal body temperature.

Microcrystalline Wax should be used over one of the Chestnut Products’ sanding sealers and allowed to dry (about 20 minutes) before buffing to a shine.

For best results apply a very thin coat, spreading the wax evenly over the entire surface.

Microcrystalline Wax can also be used on the buffing wheel system. In this situation use the A and B Wheel as normal, then apply the Microcrystalline Wax to the item you are polishing. Allow 20 minutes for the wax to dry then buff and normal using the C Wheel. You can use the same C Wheel for both Microcrystalline Wax and the Carnuaba Wax Stick.

Microcrystalline Wax has been tested to the EN71 Part 3 regulations regarding coatings used on toys.

-

Getting a good base for your finishing is essential when you want to get a great finish. Sometimes the piece you’re working on makes that more difficult due to its shape or size or for many other reasons.

Or sometimes you just want a quicker, cleaner method of applying a sealer.

That’s where Cellulose Sanding Sealer in an aerosol comes into its own. Basically the same product as in the tin, it has all the same benefits of quick drying and universal compatibility, it also has the added advantage of being easier both to apply and to get an even coating.

Use it before applying waxes, lacquers and polishes for a more durable final finish.

Getting a good base for your finishing is essential when you want to get a great finish. Sometimes the piece you’re working on makes that more difficult due to its shape or size or for many other reasons.

Or sometimes you just want a quicker, cleaner method of applying a sealer.

That’s where Cellulose Sanding Sealer in an aerosol comes into its own. Basically the same product as in the tin, it has all the same benefits of quick drying and universal compatibility, it also has the added advantage of being easier both to apply and to get an even coating.

Use it before applying waxes, lacquers and polishes for a more durable final finish.

-

Hampshire Sheen Embellishing Wax are ideal for enhancing open grained decorative items from woods such as Oak or Ash or woods with added texture. They work brilliantly in combination with the Intrinsic Colour Collection and this selection available in nine colours are a great, easy to apply alternative to gilt creams. Supplied in 60g tins.

Hampshire Sheen Embellishing Wax are ideal for enhancing open grained decorative items from woods such as Oak or Ash or woods with added texture. They work brilliantly in combination with the Intrinsic Colour Collection and this selection available in nine colours are a great, easy to apply alternative to gilt creams. Supplied in 60g tins. -

End Seal is an emulsified paraffin wax used the seal the ends of freshly cut timber to slow down the drying process and reduce the risk of the timber splitting. It can also be used on work-in-progress that is being left unfinished where there is a risk of the timber splitting. Apply it liberally, normally by brush but it can be sprayed if needed, usually to the smallest surface of the timber which will normally be the end grain where moisture is most likely to escape from. Sealing the surface will encourage the moisture to escape via the larger areas which will result in a slower exit.

End Seal is an emulsified paraffin wax used the seal the ends of freshly cut timber to slow down the drying process and reduce the risk of the timber splitting. It can also be used on work-in-progress that is being left unfinished where there is a risk of the timber splitting. Apply it liberally, normally by brush but it can be sprayed if needed, usually to the smallest surface of the timber which will normally be the end grain where moisture is most likely to escape from. Sealing the surface will encourage the moisture to escape via the larger areas which will result in a slower exit. -

This is the same wax Chestnut use in the tinned version of Microcrystalline Wax but in a solid block form with no solvent. This means there’s no waiting around for it to dry before buffing it.

Like the original version, this wax should be used very sparingly, a little goes a very long way and once applied it might even be necessary to spread it thinner using Safety Cloth (the texture of this makes it ideal for this purpose).

The Microcrystalline Wax Stick is also perfect for use on the Buffing Wheel System, use it on Wheel C to buff up to a brilliant, hard wearing finish.

This is the same wax Chestnut use in the tinned version of Microcrystalline Wax but in a solid block form with no solvent. This means there’s no waiting around for it to dry before buffing it.

Like the original version, this wax should be used very sparingly, a little goes a very long way and once applied it might even be necessary to spread it thinner using Safety Cloth (the texture of this makes it ideal for this purpose).

The Microcrystalline Wax Stick is also perfect for use on the Buffing Wheel System, use it on Wheel C to buff up to a brilliant, hard wearing finish. -

When you need to protect your work but don’t want an overpowering shine on it, Acrylic Satin Lacquer is an ideal choice. With the benefit of an easy aerosol application, especially useful on awkward shapes, this is a hard wearing water based lacquer that will protect whatever it’s put onto, leaving an attractive satin sheen.

Acrylic Satin Lacquer is touch dry and dust free in about five minutes and hard dry about 20 minutes, ready for a second coat if needed after a light cut back with a fine abrasive.

For best results it should be used over either Cellulose Sanding Sealer or the Acrylic Sanding Sealer aerosol.

If you have a change of heart on the finish the lacquer can be brought to a gloss by using either Burnishing Cream or the Buffing Wheel Kit. Or you can simply apply a coat of Acrylic Gloss Lacquer!

When you need to protect your work but don’t want an overpowering shine on it, Acrylic Satin Lacquer is an ideal choice. With the benefit of an easy aerosol application, especially useful on awkward shapes, this is a hard wearing water based lacquer that will protect whatever it’s put onto, leaving an attractive satin sheen.

Acrylic Satin Lacquer is touch dry and dust free in about five minutes and hard dry about 20 minutes, ready for a second coat if needed after a light cut back with a fine abrasive.

For best results it should be used over either Cellulose Sanding Sealer or the Acrylic Sanding Sealer aerosol.

If you have a change of heart on the finish the lacquer can be brought to a gloss by using either Burnishing Cream or the Buffing Wheel Kit. Or you can simply apply a coat of Acrylic Gloss Lacquer!

-

Cut’n’Polish is a blend of two waxes with a fine abrasive held in suspension within them. This is a soft wax designed to stay ‘wet’ slightly longer during application, allowing it to lubricate the abrasive to give a very fine cut to the timber and also to collect any dust generated during use and some subsequent sanding, preventing it from entering the workshop atmosphere. On bare wood; sand to 240 grit as normal, apply a coat of Cut’n’Polish with the lathe stopped, then switch on the lathe and buff to a soft sheen whilst smoothing the timber at the same time. On sealed wood apply after the sealer in the same way, polishing to a slightly higher shine. Cut’n’Polish dries almost immediately and can be overcoated with Friction Polish or any Chestnut waxes for a higher shine.

Cut’n’Polish is a blend of two waxes with a fine abrasive held in suspension within them. This is a soft wax designed to stay ‘wet’ slightly longer during application, allowing it to lubricate the abrasive to give a very fine cut to the timber and also to collect any dust generated during use and some subsequent sanding, preventing it from entering the workshop atmosphere. On bare wood; sand to 240 grit as normal, apply a coat of Cut’n’Polish with the lathe stopped, then switch on the lathe and buff to a soft sheen whilst smoothing the timber at the same time. On sealed wood apply after the sealer in the same way, polishing to a slightly higher shine. Cut’n’Polish dries almost immediately and can be overcoated with Friction Polish or any Chestnut waxes for a higher shine.

-

If you’re looking for a finish that won’t change the colour of your timber, won’t overpower the natural beauty of the wood with a high gloss but will still protect the timber and smell nice, well, you’re in the right place! Lemon Oil is a clear, low build finish. By that we mean that it’s a very thin liquid with a very low solids content, so no matter how much you apply it’s not going to build up to a discernible visible film on the surface. Instead it soaks in and seals the surface, offering a level of water resistance and protection against handling. Normally applied with a brush or a cloth it’s very easy to use and covers well and doesn’t usually show overlaps, so it’s ideal for large areas which often look better without a high gloss. And as you might expect, it has a pleasant lemon aroma too, although this does fade after a while.

If you’re looking for a finish that won’t change the colour of your timber, won’t overpower the natural beauty of the wood with a high gloss but will still protect the timber and smell nice, well, you’re in the right place! Lemon Oil is a clear, low build finish. By that we mean that it’s a very thin liquid with a very low solids content, so no matter how much you apply it’s not going to build up to a discernible visible film on the surface. Instead it soaks in and seals the surface, offering a level of water resistance and protection against handling. Normally applied with a brush or a cloth it’s very easy to use and covers well and doesn’t usually show overlaps, so it’s ideal for large areas which often look better without a high gloss. And as you might expect, it has a pleasant lemon aroma too, although this does fade after a while.

-

Ebonising Lacquer is a tough, hard-wearing water-based lacquer. It is heavily pigmented so that when it is dry it emulates the classic satin look of ebony.

Usually applied over a sanding sealer (either Cellulose Sanding Sealer or Acrylic Sanding Sealer aerosol) it is touch dry in about five minutes and hard dry after twenty minutes.

Although heavily pigmented it is not paint and will still allow the grain of the timber to show through, rather than obliterating it completely.

Liming Wax and Gilt Cream can be applied over Ebonising Lacquer to give a pleasing, eye-catching yet very simple artistic effect.

If a bright gloss finish is required from Ebonising Lacquer this is best achieved by using Burnishing Cream on the lacquer with will polish it up to a high gloss.

Acrylic Gloss Lacquer can also be applied on top of Ebonising Lacquer, as can WoodWax 22 and Microcrystalline Wax.

Ebonising Lacquer is a tough, hard-wearing water-based lacquer. It is heavily pigmented so that when it is dry it emulates the classic satin look of ebony.

Usually applied over a sanding sealer (either Cellulose Sanding Sealer or Acrylic Sanding Sealer aerosol) it is touch dry in about five minutes and hard dry after twenty minutes.

Although heavily pigmented it is not paint and will still allow the grain of the timber to show through, rather than obliterating it completely.

Liming Wax and Gilt Cream can be applied over Ebonising Lacquer to give a pleasing, eye-catching yet very simple artistic effect.

If a bright gloss finish is required from Ebonising Lacquer this is best achieved by using Burnishing Cream on the lacquer with will polish it up to a high gloss.

Acrylic Gloss Lacquer can also be applied on top of Ebonising Lacquer, as can WoodWax 22 and Microcrystalline Wax.

-

If you don’t have access to spraying equipment, this aerosol lacquer will give you a great finish quickly and easily. A spray application is particularly relevant when trying to achieve the best gloss finish possible. Acrylic Gloss Lacquer is a high build water based lacquer specially adapted to give the best delivery through the nozzle (chosen to give excellent results without spitting, spotting or clogging in normal use) without, of course, the use of CFCs.

The lacquer itself dries quickly to give a high gloss finish straight from the can which has the benefit of being extremely hard wearing and durable – so much so that it can be used on items that will be kept outdoors or used in areas where moisture could damage other finishes.

Acrylic Gloss Lacquer is touch dry and tack free in around five minutes and hard dry in twenty minutes, ready for a second coat if needed after a light rubdown with a fine abrasive.

The sheen level can be increased if required by using Burnishing Cream (which will not affect the durability) or, after allowing 24 hours to ensure it is completely hard dry, by using it in conjunction with the Buffing Wheel Kit.

If you don’t have access to spraying equipment, this aerosol lacquer will give you a great finish quickly and easily. A spray application is particularly relevant when trying to achieve the best gloss finish possible. Acrylic Gloss Lacquer is a high build water based lacquer specially adapted to give the best delivery through the nozzle (chosen to give excellent results without spitting, spotting or clogging in normal use) without, of course, the use of CFCs.

The lacquer itself dries quickly to give a high gloss finish straight from the can which has the benefit of being extremely hard wearing and durable – so much so that it can be used on items that will be kept outdoors or used in areas where moisture could damage other finishes.

Acrylic Gloss Lacquer is touch dry and tack free in around five minutes and hard dry in twenty minutes, ready for a second coat if needed after a light rubdown with a fine abrasive.

The sheen level can be increased if required by using Burnishing Cream (which will not affect the durability) or, after allowing 24 hours to ensure it is completely hard dry, by using it in conjunction with the Buffing Wheel Kit.

-

Fine finishing starts with good preparation! Use these mildly abrasive pads after sanding for that final smoothing process to give a near-perfect surface prior to applying any finish. Very long lasting, these pads are also very flexible and do not crumble, thus avoiding any fear of contamination of your work. Exercise care when using these pads with the lathe revolving.

Fine finishing starts with good preparation! Use these mildly abrasive pads after sanding for that final smoothing process to give a near-perfect surface prior to applying any finish. Very long lasting, these pads are also very flexible and do not crumble, thus avoiding any fear of contamination of your work. Exercise care when using these pads with the lathe revolving. -

WoodWax 22 contains beeswax (for shine) and carnauba wax (for hardness). Blended together in a solvent to produce a soft creamy paste. This makes it very easy to apply over any surface.

WoodWax 22 is quick drying enough to be applied onto unsealed wood but works best on one of Chestnuts sanding sealers.

If working on the lathe the wax should be applied with the lathe stopped.

Apply using a cloth (Safety Cloth or Stockinette works well with this); the wax spreads easily over the surface, after about 20 seconds it starts to drag slightly. This means it is ready to buff up; if you haven’t covered the whole piece by then don’t worry, just take a little more wax from the tin and carry on applying, the wax won’t mind waiting!

It’s best to buff WoodWax 22 as soon as you can; that way any surplus wax that might have been applied will be removed, allowing the shine to really show through.

If working on the lathe Safety Cloth should be used for the buffing process and let the lathe do the work for you. Off the lathe Safety Cloth or Stockinette can be used.

A second or even third coat of wax can be applied if required, leaving about twenty minutes between coats. After three coats the finish can become softer and will mark very easily.

WoodWax 22 contains beeswax (for shine) and carnauba wax (for hardness). Blended together in a solvent to produce a soft creamy paste. This makes it very easy to apply over any surface.

WoodWax 22 is quick drying enough to be applied onto unsealed wood but works best on one of Chestnuts sanding sealers.

If working on the lathe the wax should be applied with the lathe stopped.

Apply using a cloth (Safety Cloth or Stockinette works well with this); the wax spreads easily over the surface, after about 20 seconds it starts to drag slightly. This means it is ready to buff up; if you haven’t covered the whole piece by then don’t worry, just take a little more wax from the tin and carry on applying, the wax won’t mind waiting!

It’s best to buff WoodWax 22 as soon as you can; that way any surplus wax that might have been applied will be removed, allowing the shine to really show through.

If working on the lathe Safety Cloth should be used for the buffing process and let the lathe do the work for you. Off the lathe Safety Cloth or Stockinette can be used.

A second or even third coat of wax can be applied if required, leaving about twenty minutes between coats. After three coats the finish can become softer and will mark very easily.

-

This is an oil type finish similar to Danish oil but nothing like it. This product is designed to be hand rubbed on to raw timber, giving a finish with a hard, bright, high gloss. It will bring out amazing depth and brilliance to most timbers making the grain pop and become opalescent, vibrant, shimmering and alive. Especially when used on a fine grained, highly figure timber. And if that's not enough it does it all in a matter of minutes.

Aussie Oil is ideal for use on most small items like pendants, brooches, earrings, small turned items that cannot be fully finished on the lathe. Pens, magnifying glass handles, compacts, key rings, letter openers, in fact almost anything made of wood you can comfortably hold in your hand to polish.

As an extra added bonus, it also works brilliantly as a friction polish on the lathe.

-

Food Safe Finish is a clear, food grade mineral oil. Chestnut use a thin grade of oil to allow it to soak into bare timber which then protects it against water splashes etc whilst not tainting or affecting the food in any way. It dries to a fairly matt finish; it is however ideal to use for wet sanding and when used with a very fine abrasive it can give an exceptionally smooth surface which has its own gentle glow. Apply with a clean cloth or brush direct onto bare wood, up to three coats are recommended. If the oil sits on the surface and won’t soak in it means the timber has absorbed as much as it can and no further coats are needed. Any surplus can be removed with a clean cloth if required. Depending on the way the item is used it might be necessary to top-up the finish, especially if it is washed regularly.

Food Safe Finish is a clear, food grade mineral oil. Chestnut use a thin grade of oil to allow it to soak into bare timber which then protects it against water splashes etc whilst not tainting or affecting the food in any way. It dries to a fairly matt finish; it is however ideal to use for wet sanding and when used with a very fine abrasive it can give an exceptionally smooth surface which has its own gentle glow. Apply with a clean cloth or brush direct onto bare wood, up to three coats are recommended. If the oil sits on the surface and won’t soak in it means the timber has absorbed as much as it can and no further coats are needed. Any surplus can be removed with a clean cloth if required. Depending on the way the item is used it might be necessary to top-up the finish, especially if it is washed regularly.

-

Chestnut Finishing Oil is Chestnuts' version of Danish Oil* and uses Tung Oil as its base but with the addition of solvents and driers. This aids the drying of the product and speeds it up dramatically, so that it’s dry within eight hours. It has a pale amber colour and dries to a hard yet flexible film which is very hardwearing and water resistant.

For a high gloss finish apply several coats with a light rub down between coats; after 5 or 6 coats a good sheen should be visible.

Finishing Oil is normally applied by cloth but on larger areas a brush can be used very successfully.

Chestnut Finishing Oil is Chestnuts' version of Danish Oil* and uses Tung Oil as its base but with the addition of solvents and driers. This aids the drying of the product and speeds it up dramatically, so that it’s dry within eight hours. It has a pale amber colour and dries to a hard yet flexible film which is very hardwearing and water resistant.

For a high gloss finish apply several coats with a light rub down between coats; after 5 or 6 coats a good sheen should be visible.

Finishing Oil is normally applied by cloth but on larger areas a brush can be used very successfully.

-

Citrus Burnishing oil can be easily applied and then burnished dry in a matter of minutes, and can be overcoated with waxes or lacquers if you wish. Use multiple coats for a water and oil resistant finish suitable for salad, fruit and snack bowls. Easy to apply; Over 50% Tung Oil; Food Safe when dry; Fresh smell when dry, fading over time; Deeply penetrating and protecting; Will not chip, flake or peel; Naturally water and oil resistant when cured. Supplied in a 500ml (17.6oz) cone top bottle.

Citrus Burnishing oil can be easily applied and then burnished dry in a matter of minutes, and can be overcoated with waxes or lacquers if you wish. Use multiple coats for a water and oil resistant finish suitable for salad, fruit and snack bowls. Easy to apply; Over 50% Tung Oil; Food Safe when dry; Fresh smell when dry, fading over time; Deeply penetrating and protecting; Will not chip, flake or peel; Naturally water and oil resistant when cured. Supplied in a 500ml (17.6oz) cone top bottle. -

The finest of Steel Wool, very low crumble and virtually oil free to ensure there is no contamination of your work. Use it after sanding with abrasive sheets to give an ultra smooth surface, or to apply waxes to smooth the timber whilst applying a thin coat. Steel Wool burns very quickly and easily; keep it away from sources of combustion (i.e. sparks etc). Always use a knife or scissors to cut Steel Wool

The finest of Steel Wool, very low crumble and virtually oil free to ensure there is no contamination of your work. Use it after sanding with abrasive sheets to give an ultra smooth surface, or to apply waxes to smooth the timber whilst applying a thin coat. Steel Wool burns very quickly and easily; keep it away from sources of combustion (i.e. sparks etc). Always use a knife or scissors to cut Steel Wool -

A penetrative, nourishing, quality finishing oil which reflects the original, heavy-oil formulations that traditional Danish Oils were renowned for. As a clear finish will richly enhance the existing woodcolour/s. For best results, requires quality dry-sand surface preparation; using 600 /1200 / 1500 grit papers (the finer the better) Upon curing/drying (min. 14 days) makes for ideally prepared surface for further (optional) Waxing/Polishing.

A penetrative, nourishing, quality finishing oil which reflects the original, heavy-oil formulations that traditional Danish Oils were renowned for. As a clear finish will richly enhance the existing woodcolour/s. For best results, requires quality dry-sand surface preparation; using 600 /1200 / 1500 grit papers (the finer the better) Upon curing/drying (min. 14 days) makes for ideally prepared surface for further (optional) Waxing/Polishing.

-

Melamine Lacquer can be a bit fiddly to apply and there’s no better way than spraying it. If you don’t have access to spray equipment then this aerosol version is the ideal way.

Melamine Gloss Lacquer will quickly build to a bright gloss finish and dries in a matter of minutes.

Touch dry and safe to handle within five minutes the lacquer chemically cures to give a tougher finish. The lacquer achieves practically all of this (about 90%) within seven days, after which the process slows and can take up to another two weeks to fully complete.

Best used over a Cellulose Sanding Sealer (brushing or aerosol) and can be overcoated with a wax for a softer tactile feel.

Melamine Lacquer can be a bit fiddly to apply and there’s no better way than spraying it. If you don’t have access to spray equipment then this aerosol version is the ideal way.

Melamine Gloss Lacquer will quickly build to a bright gloss finish and dries in a matter of minutes.

Touch dry and safe to handle within five minutes the lacquer chemically cures to give a tougher finish. The lacquer achieves practically all of this (about 90%) within seven days, after which the process slows and can take up to another two weeks to fully complete.

Best used over a Cellulose Sanding Sealer (brushing or aerosol) and can be overcoated with a wax for a softer tactile feel.

-

Liberon Black Patinating Wax is used for adding a coloured finish, highlighting areas or creating striking effects on all types of interior materials. It is ideal for ageing modern furniture, disguising repairs to old and new furniture, and highlighting areas on finished pieces and decorative carvings. It is suitable for use on wood, metal, gilt, plaster, tone, MDF and papier-mâché.

Liberon Black Patinating Wax is used for adding a coloured finish, highlighting areas or creating striking effects on all types of interior materials. It is ideal for ageing modern furniture, disguising repairs to old and new furniture, and highlighting areas on finished pieces and decorative carvings. It is suitable for use on wood, metal, gilt, plaster, tone, MDF and papier-mâché.

-

Hampshire Sheen Intrinsic Colours being water based, they are non-flammable, environmentally friendly and afford you a long working time. They sink deeply into the wood and preserve the appearance of the figure in the wood, releasing the hidden subtleties. Apply more than one coat of dye to build up depth of colour, and add a black or earth undercoat for an even more dramatic effect. For the adventurous colourist, Intrinsic Colours can be mixed together to create even more shades or thinned with water for a lighter shade.

Hampshire Sheen Intrinsic Colours being water based, they are non-flammable, environmentally friendly and afford you a long working time. They sink deeply into the wood and preserve the appearance of the figure in the wood, releasing the hidden subtleties. Apply more than one coat of dye to build up depth of colour, and add a black or earth undercoat for an even more dramatic effect. For the adventurous colourist, Intrinsic Colours can be mixed together to create even more shades or thinned with water for a lighter shade. -

Tung Oil, or Chinese Wood Oil as it’s sometimes called, is a natural oil derived from the seed of the nut of the tung tree. The jury is out as to whether it can spark a nut allergy. Tung Oil air dries to form a tough, hard film that has a fairly strong amber tint. Because it doesn’t have any solvent or driers in it it can take a while to dry, and dependant on conditions this can be up to a week although 48 hours is more common. As with most finishes a thinner coat will dry quicker. Normally applied with a brush or cloth.

Tung Oil, or Chinese Wood Oil as it’s sometimes called, is a natural oil derived from the seed of the nut of the tung tree. The jury is out as to whether it can spark a nut allergy. Tung Oil air dries to form a tough, hard film that has a fairly strong amber tint. Because it doesn’t have any solvent or driers in it it can take a while to dry, and dependant on conditions this can be up to a week although 48 hours is more common. As with most finishes a thinner coat will dry quicker. Normally applied with a brush or cloth. -

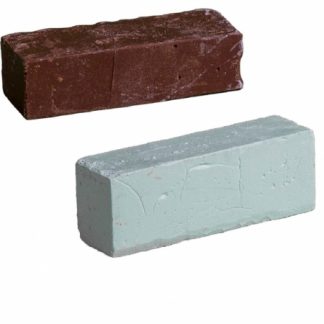

These compounds are designed to co-ordinate with the cloth used in the Buffing Wheels and Dome Buffs to give an exceptional cut and prepare the surface to a very smooth finish prior to using wax. Compound 1 -the brown one – (sometimes referred to as tripoli) is used with the ‘A’ Wheel/Dome to help smooth the applied finish. Avoid overloading the wheel/dome where possible to prevent a build up of the compound. If this happens it can be removed by either washing in soapy water or abrading the edge of the wheel with a coarse abrasive. Do not use on very open grained light coloured timber as the compound can get lodged in the grain and colour the piece. Compound 2 – the white one – (sometimes referred to as white diamond) acts as a cleanser to remove any traces of Compound 1 left on the surface (but not from the grain) and also has a very fine abrasive contained in it which smooths the work, leaving a semi-gloss finish and a superb foundation for the top coat of wax. Use Compound 2 sparingly, too much on the wheel will result in smears on the surface of your work which can be removed with buffing but this can be very time consuming and frustrating. It’s always best to apply a little and add more if needed.

These compounds are designed to co-ordinate with the cloth used in the Buffing Wheels and Dome Buffs to give an exceptional cut and prepare the surface to a very smooth finish prior to using wax. Compound 1 -the brown one – (sometimes referred to as tripoli) is used with the ‘A’ Wheel/Dome to help smooth the applied finish. Avoid overloading the wheel/dome where possible to prevent a build up of the compound. If this happens it can be removed by either washing in soapy water or abrading the edge of the wheel with a coarse abrasive. Do not use on very open grained light coloured timber as the compound can get lodged in the grain and colour the piece. Compound 2 – the white one – (sometimes referred to as white diamond) acts as a cleanser to remove any traces of Compound 1 left on the surface (but not from the grain) and also has a very fine abrasive contained in it which smooths the work, leaving a semi-gloss finish and a superb foundation for the top coat of wax. Use Compound 2 sparingly, too much on the wheel will result in smears on the surface of your work which can be removed with buffing but this can be very time consuming and frustrating. It’s always best to apply a little and add more if needed. -

This creamy liquid has a very mild abrasive within it which acts like ‘liquid sandpaper’ on finished surfaces, cutting back and cleaning the finish and elevating it to a glossier, brighter finish. It can be used to smooth Cellulose Sanding Sealer prior to applying wax or Friction Polish, or, after allowing a suitable time to dry, on any of the lacquers, Friction Polish, Finishing Oil or Hard Wax Oil. A deep finish can be achieved using Burnishing Cream on a coat of Melamine Lacquer, then a coat of Friction Polish and finally the Burnishing Cream again. Use it sparingly so as not to over lubricate the surface and be sure to shake the bottle before use. It is not advisable to use a lacquer on top of a surface that has had Burnishing Cream used on it.

This creamy liquid has a very mild abrasive within it which acts like ‘liquid sandpaper’ on finished surfaces, cutting back and cleaning the finish and elevating it to a glossier, brighter finish. It can be used to smooth Cellulose Sanding Sealer prior to applying wax or Friction Polish, or, after allowing a suitable time to dry, on any of the lacquers, Friction Polish, Finishing Oil or Hard Wax Oil. A deep finish can be achieved using Burnishing Cream on a coat of Melamine Lacquer, then a coat of Friction Polish and finally the Burnishing Cream again. Use it sparingly so as not to over lubricate the surface and be sure to shake the bottle before use. It is not advisable to use a lacquer on top of a surface that has had Burnishing Cream used on it.

-

The ideal way to experiment with the different colours available to decide which ones you prefer, the Spirit Stain Kit contains one bottle (min. contents 25ml) of each of the nine colours. These are exactly the same stain as in the bigger bottles and will intermix if you want to vary the shades available.

The stains are very fade resistant, quick drying and non-grain raising.

-

Shellac Sanding Sealer is the traditional way of sealing timber prior to applying a polish or a wax.

Chestnuts version has a high percentage of real shellac which means it does the job extremely well, dissolved in an ethanol solution to make it easy to apply and quick drying.

Applied by cloth, brush or spray it dries in about 20 minutes, making it very popular for cabinet and architectural work as it is easy to keep a wet edge running. It is also popular with woodturners and highlights the natural grain of the timber extremely well.

Sand back lightly after application and apply Friction Polish, French Polish or any of Chestnuts waxes on top.

Conforms to EN71 Part 3 – suitable for toys and nursery furniture.

Shellac Sanding Sealer is the traditional way of sealing timber prior to applying a polish or a wax.

Chestnuts version has a high percentage of real shellac which means it does the job extremely well, dissolved in an ethanol solution to make it easy to apply and quick drying.

Applied by cloth, brush or spray it dries in about 20 minutes, making it very popular for cabinet and architectural work as it is easy to keep a wet edge running. It is also popular with woodturners and highlights the natural grain of the timber extremely well.

Sand back lightly after application and apply Friction Polish, French Polish or any of Chestnuts waxes on top.

Conforms to EN71 Part 3 – suitable for toys and nursery furniture.

-

Gilt Creams are a creamy, waxy paste with metallic flakes and pigments in them, giving a rich, lustrous finish to whatever they are applied to. The can be used for a ‘limed’ effect over a lacquer to give a high contrast effect, or uniformly over a piece and polished to a bright shine once dried. Available in

Gilt Creams are a creamy, waxy paste with metallic flakes and pigments in them, giving a rich, lustrous finish to whatever they are applied to. The can be used for a ‘limed’ effect over a lacquer to give a high contrast effect, or uniformly over a piece and polished to a bright shine once dried. Available in- Gold

- Silver

- Copper

-

These Dispensing Nozzles are, in fact, almost indispensable! They fit onto any of Chestnuts' plastic bottles in the 250ml, 500ml and 1 ltr sizes, simply replacing the existing cap. Cut the tip off to the size you want and use the handy cover to reseal them when not in use. A useful by product of using these is that if you knock a bottle over the amount you lose through the small nozzle will be much less than without it. Just don’t forget to take the nozzle off the bottle before you throw it away so that you can re-use it! These nozzles are not child resistant, the correct closure should be replaced when the product is not in use.

These Dispensing Nozzles are, in fact, almost indispensable! They fit onto any of Chestnuts' plastic bottles in the 250ml, 500ml and 1 ltr sizes, simply replacing the existing cap. Cut the tip off to the size you want and use the handy cover to reseal them when not in use. A useful by product of using these is that if you knock a bottle over the amount you lose through the small nozzle will be much less than without it. Just don’t forget to take the nozzle off the bottle before you throw it away so that you can re-use it! These nozzles are not child resistant, the correct closure should be replaced when the product is not in use. -

Quick drying Microcrystalline Wax is an ideal protective finish for many different projects and has many uses besides wood. Both Fingerprint and water resistant, Microcrystalline Wax is a hard wearing overcoat to wax and other finishes for an extra level of gloss and protection to your decorative wood items. Just a little of the product goes a very long way, so use it sparingly!

Quick drying Microcrystalline Wax is an ideal protective finish for many different projects and has many uses besides wood. Both Fingerprint and water resistant, Microcrystalline Wax is a hard wearing overcoat to wax and other finishes for an extra level of gloss and protection to your decorative wood items. Just a little of the product goes a very long way, so use it sparingly! -

This kit gets you started on the road to buffing – all you need to supply is the lathe, a chuck and something to buff! Inside the kit you get the mandrels for holding the Buffing Wheels in the chuck. One of each buffing wheel (A, B and C) are included in the 8 inch size, complete with all the fixings attached to fit into the Mandrels. A bar of each of the compounds is included to get you started, these will last a long time so no need to worry about getting spares yet (although all of the items in the kit are available separately when you need to get them). Next is a stick of carnauba wax for that final gloss finish. Last but not least is a full set of instructions on how to use the kit to get the best from it.

This kit gets you started on the road to buffing – all you need to supply is the lathe, a chuck and something to buff! Inside the kit you get the mandrels for holding the Buffing Wheels in the chuck. One of each buffing wheel (A, B and C) are included in the 8 inch size, complete with all the fixings attached to fit into the Mandrels. A bar of each of the compounds is included to get you started, these will last a long time so no need to worry about getting spares yet (although all of the items in the kit are available separately when you need to get them). Next is a stick of carnauba wax for that final gloss finish. Last but not least is a full set of instructions on how to use the kit to get the best from it. -

If you need to get away from the smell and flammability of our cellulose based lacquers this is an ideal option.

This water based lacquer has virtually no smell and is totally non-flammable. Don’t be fooled though, this product is extremely hard wearing and gives a full gloss finish.

Being water based it is slightly slower drying, taking about twenty minutes to be touch dry. If you want to apply a second coat it should be left two hours before doing so, although a wax can be applied if required after about thirty minutes.

This product can be sprayed if suitable equipment is available, or can be applied by cloth or brush. We recommend foam brushes for application as this keeps the foaming action of acrylics to a minimum.

If you need to get away from the smell and flammability of our cellulose based lacquers this is an ideal option.

This water based lacquer has virtually no smell and is totally non-flammable. Don’t be fooled though, this product is extremely hard wearing and gives a full gloss finish.

Being water based it is slightly slower drying, taking about twenty minutes to be touch dry. If you want to apply a second coat it should be left two hours before doing so, although a wax can be applied if required after about thirty minutes.

This product can be sprayed if suitable equipment is available, or can be applied by cloth or brush. We recommend foam brushes for application as this keeps the foaming action of acrylics to a minimum.

-

Ever wished you had a finish that was as easy to use as shellac but with the durability of polyurethane? Well wish no more, because here it is.

This unique Hardened Shellac creates a film with a high resistance to heat, water and alcohol, yet it is used in exactly the same was as any normal shellac. It can be applied with a rubber as French polish, brushed, sprayed and dipped.

HOW IS THIS POSSIBLE? After shellac has been dissolved in ethanol* it is possible to introduce additives that cause the shellac to cross link after it has dried. This cross linking takes about 20 days to completely cure, less in hot weather.

USES: Ideal for table tops and other horizontal surfaces such as dresser and desk tops, etc. Also brilliant for use on guitars, lutes, harps and many other musical instruments where a traditional finish is required and good resonance qualities are essential.

NEW IMPROVED FORMULA In February 2009 U-beaut began adding a plasticiser to Hard Shellac. This gives elasticity to the cured finish, to combat crazing on the thin walls of musical instruments, whilst still having the same high resistance to marking from water, alcohol and heat it has always had.

-

Liberon Finishing Oil is a blend of high quality oils for use on all interior wood and turned woodwork. Used to nourish and enhance the colour of the wood, it is suitable for use on kitchen tables and bathroom furniture, and can also be applied to cork, stone and terracotta. Water, heat, alcohol and food acid resistant, it gives a matt, satin or gloss finish depending upon the number of coats applied. Ideal for surfaces requiring a hard wearing and water-resistant finishes.

Liberon Finishing Oil is a blend of high quality oils for use on all interior wood and turned woodwork. Used to nourish and enhance the colour of the wood, it is suitable for use on kitchen tables and bathroom furniture, and can also be applied to cork, stone and terracotta. Water, heat, alcohol and food acid resistant, it gives a matt, satin or gloss finish depending upon the number of coats applied. Ideal for surfaces requiring a hard wearing and water-resistant finishes.

-

NyWeb pads are a non-woven nylon webbing with an abrasive – either silicon carbide or aluminium oxide – embedded into them to give an exactly defined cut.

NyWeb pads are a non-woven nylon webbing with an abrasive – either silicon carbide or aluminium oxide – embedded into them to give an exactly defined cut.- The Green pads are 400 grit

- The Red pads are 600 grit

- The Orange pads are 1000 grit

- The White pads do not contain an abrasive and are thus technically non-abrasive, but the very texture of the pads gives them an incredibly fine – but immeasurable – cut.

-

These unstitched, cotton mops are ideal for polishing the insides of bowls and boxes etc to achieve the same great finish on the inside as on the outside when using the Buffing Wheel kit, without the fear of the item being snatched from your hands by the larger Buffing Wheels. All of the domes share the same thread as in the large mandrel and the small mandrel so all parts are completely interchangeable. Due to the smaller size of these dome buffs they will require more time and sometimes more speed on the lathe to be able to match the finish given by the larger wheels. Dome Buff A is used with compound 1 to cut back the applied finish and remove any minor blemishes left behind by sanding. Dome Buff B is used with Compound 2 to cleanse the piece and also to prepare for the final polish coat by giving an exceptionally smooth surface. Dome Buff C is used with either the Carnauba wax stick, microcrystalline wax or Microcrystalline Wax Stick to give a wonderful, long lasting shine.

These unstitched, cotton mops are ideal for polishing the insides of bowls and boxes etc to achieve the same great finish on the inside as on the outside when using the Buffing Wheel kit, without the fear of the item being snatched from your hands by the larger Buffing Wheels. All of the domes share the same thread as in the large mandrel and the small mandrel so all parts are completely interchangeable. Due to the smaller size of these dome buffs they will require more time and sometimes more speed on the lathe to be able to match the finish given by the larger wheels. Dome Buff A is used with compound 1 to cut back the applied finish and remove any minor blemishes left behind by sanding. Dome Buff B is used with Compound 2 to cleanse the piece and also to prepare for the final polish coat by giving an exceptionally smooth surface. Dome Buff C is used with either the Carnauba wax stick, microcrystalline wax or Microcrystalline Wax Stick to give a wonderful, long lasting shine. -

If you’re looking for a clear finish that is tough, hardwearing and gives a bright gloss yet is still very easy to apply, even on larger areas, you’re in the right place.

Hard Wax Oil is a particular blend of tough oils combined with special waxes which dries to an exceptionally resilient finish. Ideal for anything that is going to be subjected to water splashes or a lot of handling this oil may not be indestructible but it will stand up to a lot of abuse.

It retains the ease of application typical of an oil and it stays wet long enough to get a smooth, even finish – even on large areas – but is touch dry and tack free in about 20 minutes, and better yet is ready for a second coat after about four hours (in normal conditions).

Hard Wax Oil will build to a bright gloss finish after 2-3 coats. Rub down lightly between coats with a fine abrasive. Once hard dry (allow at least 24 hours) it can be brought to an even brighter shine using either the buffing wheel system or burnishing cream.

For a not-quite-so-bright finish use a mild abrasive to reduce the gloss. For best results lubricate the abrasive with microcrystalline wax to retain the toughness of the oil.

If you’re looking for a clear finish that is tough, hardwearing and gives a bright gloss yet is still very easy to apply, even on larger areas, you’re in the right place.

Hard Wax Oil is a particular blend of tough oils combined with special waxes which dries to an exceptionally resilient finish. Ideal for anything that is going to be subjected to water splashes or a lot of handling this oil may not be indestructible but it will stand up to a lot of abuse.

It retains the ease of application typical of an oil and it stays wet long enough to get a smooth, even finish – even on large areas – but is touch dry and tack free in about 20 minutes, and better yet is ready for a second coat after about four hours (in normal conditions).

Hard Wax Oil will build to a bright gloss finish after 2-3 coats. Rub down lightly between coats with a fine abrasive. Once hard dry (allow at least 24 hours) it can be brought to an even brighter shine using either the buffing wheel system or burnishing cream.

For a not-quite-so-bright finish use a mild abrasive to reduce the gloss. For best results lubricate the abrasive with microcrystalline wax to retain the toughness of the oil.

-

This water based sanding sealer gets the job done without the smell associated with solvent based sealers and also with no flammability issues – ideal for asthma suffers and anyone with an aversion to solvent based finishes.

Applied by cloth, brush or spray (Chestnuts' foam brushes are especially good with this) the sealer dries in about 5 minutes and can be overcoated with most compatible finishes after about 20 minutes although two hours should be left if using Acrylic Lacquer.

Acrylic Sanding Sealer sands easily with a fine abrasive and is supplied ready for use.

This water based sanding sealer gets the job done without the smell associated with solvent based sealers and also with no flammability issues – ideal for asthma suffers and anyone with an aversion to solvent based finishes.

Applied by cloth, brush or spray (Chestnuts' foam brushes are especially good with this) the sealer dries in about 5 minutes and can be overcoated with most compatible finishes after about 20 minutes although two hours should be left if using Acrylic Lacquer.

Acrylic Sanding Sealer sands easily with a fine abrasive and is supplied ready for use.

-

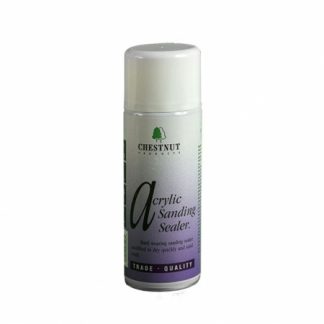

It’s important to use a sanding sealer on most items; it gives a good foundation to your piece and can help the next coat to adhere properly to the timber.

Chestnut Acrylic Sanding Sealer does this perfectly and is designed to be used with Acrylic Gloss Lacquer, Acrylic Satin Lacquer, Ebonising Lacquer, any of their polishes and any of their waxes.

Supplied in an easy to use aerosol the dried coating complies with the EN71 Part 3 regulations governing toys and nursery furniture.

Once dried lightly sand back prior to applying your top coat.

It’s important to use a sanding sealer on most items; it gives a good foundation to your piece and can help the next coat to adhere properly to the timber.

Chestnut Acrylic Sanding Sealer does this perfectly and is designed to be used with Acrylic Gloss Lacquer, Acrylic Satin Lacquer, Ebonising Lacquer, any of their polishes and any of their waxes.

Supplied in an easy to use aerosol the dried coating complies with the EN71 Part 3 regulations governing toys and nursery furniture.

Once dried lightly sand back prior to applying your top coat.

-

Out of stock

Shellawax Glow is darker than regular Shellawax (a deep honey to tan colour). It is made from a special blend of shellacs and is designed to give more depth and richness to highly figured timbers like fiddleback, birdseye, flame and quilted woods. It will also give more richness and a sense of depth to many other timbers.

Shellawax Glow is identical in use and all other respects to regular Shellawax. It is applied in the same way and has all the same properties. It can also be mixed with Shellawax Cream as an extender and thinner and can be used over EEE-Ultra Shine.

This polish may darken white woods ever so slightly, so it is a good idea to try it on a scrap piece first to make sure it doesn't darken more than you want.

USING SHELLAWAX CREAM AS A SHELLAWAX GLOW EXTENDER Shellawax Glow can be mixed with Shellawax Cream as an extender. This allows for better use of these products on large turned work and for hand rubbed work. For bowls over (6”) 150mm diam, mix the Cream and Shellawax Glow at the rate of approx 50/50 this will give you a runny cream that will stay on the surface longer and allow you more time to work it into the timber.

Use different mixing rates for various jobs 20% Cream to 80% Shellawax Glow for large platters etc up to 900mm (3’) diam and larger.

SHELLAWAX GLOW AS A THINNER Use Shellawax as a thinner for Shellawax Cream, which often thickens with use. This will also extend the life of the Cream. The slight colour difference will not effect the colour of Cream when used.

-

Out of stock

Chestnut Spray Diffusers are ideal for applying Spirit Stain; one end goes in the stain and you blow through the other end for your own mini-spray gun. Great for special decorative effects.

Chestnut Spray Diffusers are ideal for applying Spirit Stain; one end goes in the stain and you blow through the other end for your own mini-spray gun. Great for special decorative effects.